Industria del cuero para calzado

Hora de lanzamiento: 12/03/2025

Laminado de malla sin costuras, tela estereotipada, Hong Kong Bao, pegamento Bang anterior, pegamento post-Bang, compuesto de plantilla, película resaltada de transferencia de cuero, etiqueta de cuero, etc.

zapatos

Se aplica una película termofusible al pegamento de prensado de malla para zapatillas deportivas. En comparación con el proceso de costura tradicional, la adhesión es más rápida, más resistente y tiene una apariencia más atractiva. Las principales características del producto son las siguientes: A. Fácil de usar, ahorra mano de obra. B. Alta resistencia al pelado y fuerte adhesión. C. Buena elasticidad, tenacidad y resistencia al desgaste. D. Impermeable. E. Apto para PVC, poliéster, mezclas, algodón, nailon, tela, cuero y otros materiales.

tela estereotipada

El polvo termofusible es una materia prima para la producción de telas termoselladas. El cliente general suele usar especificaciones de 40 a 80 puntos para distribuirlo uniformemente sobre la tela. Después de calentarlo en el horno, el polvo termofusible se solidifica inmediatamente a temperatura ambiente y se adhiere a la tela. Las telas termoselladas, utilizadas para unir productos de cuero (como zapatos, bolsos, etc.), logran un buen efecto de adhesión sin necesidad de tratamiento superficial, manteniendo un forro resistente y suave, y eliminando las arrugas del cuero debido a la apariencia de una piel interior tensa. Con pegamento tradicional, se pueden crear arrugas en el cuero.

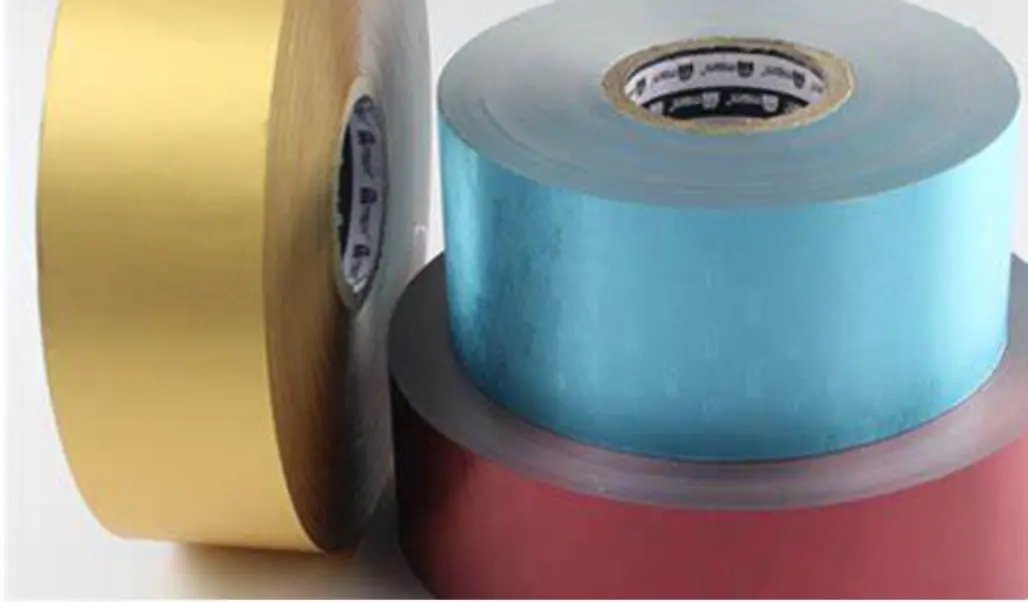

película de alto brillo

El gel termofusible se utiliza para la producción de adhesivos termofusibles, películas de alto brillo y otras materias primas esenciales. Este adhesivo ofrece una excelente elasticidad, resistencia a la deformación y las arrugas, finura, curado rápido y otras ventajas. Su película de alto brillo y brillo son muy utilizados en calzado y bolsos de cuero, entre otros productos. La malla termofusible se aplica a las plantillas, donde la tela y la base de la espuma se ajustan, ofreciendo una mayor solidez que la del pegamento convencional, resistencia al agua, limpieza en seco, protección ambiental, grosor uniforme y mayor comodidad.

pegamento para zapatos

El pegamento pre-ayuda ofrece buena resistencia ambiental, alta solidez de adhesión, rápido curado y otras ventajas, ideal para la producción en masa. Se utiliza principalmente en la cabeza del zapato para mantenerla firme y garantizar la estética y comodidad del calzado. El pegamento post-ayuda ofrece protección ambiental, buena resistencia ambiental, alta solidez de adhesión, rápido curado y otras ventajas, ideal para la producción en masa. Se utiliza principalmente para el ajuste del talón y la parte del tobillo.

1. Aplicación en calzado deportivo

En la producción de calzado deportivo, la película adhesiva termofusible se utiliza ampliamente para unir empeines, fijar plantillas y conectar tacones. El calzado deportivo suele estar fabricado con múltiples capas de materiales, como cuero sintético, tela, caucho y espuma, y la película adhesiva termofusible garantiza una unión sólida entre estos materiales.

Las ventajas de la película adhesiva termofusible en el calzado deportivo son:

Comodidad mejorada: la película adhesiva termofusible no destruirá la elasticidad del material durante el proceso de unión y puede mantener la comodidad del calzado deportivo.

Gran durabilidad: la película adhesiva termofusible puede soportar la fricción y el estiramiento a largo plazo del calzado deportivo, mejorando la durabilidad de los zapatos.

Prototipado rápido: la película adhesiva termofusible tiene un tiempo de curado corto, lo que puede mejorar la eficiencia de producción.

2. Aplicación en calzado de cuero

En la fabricación de calzado de cuero, la película adhesiva termofusible se utiliza a menudo para unir empeines y suelas, así como para superponer el cuero con otros materiales. Gracias a la suavidad y la facilidad de deformación del cuero, la película adhesiva termofusible conserva eficazmente su aspecto y tacto naturales durante el proceso de unión. Además, evita los problemas de contaminación causados por los compuestos orgánicos volátiles (COV) presentes en los pegamentos tradicionales, cumpliendo así con los requisitos de protección ambiental.

Las ventajas de la película adhesiva termofusible en el calzado de cuero incluyen:

Mejora de la estética: la película adhesiva termofusible puede mantener lisa la superficie del cuero y evitar que el pegamento desbordado afecte la apariencia de la parte superior.

Protección del medio ambiente: la película adhesiva termofusible no es tóxica y no tiene olor irritante, lo que cumple con los requisitos de los consumidores modernos de protección del medio ambiente y la salud.

No es fácil de deformar: en comparación con los métodos de unión tradicionales, la película adhesiva termofusible puede evitar la deformación del cuero causada por el contacto con el pegamento.

3. Aplicación en sandalias y pantuflas

La fabricación de sandalias y pantuflas suele requerir la unión de diferentes materiales, como caucho, tela, materiales sintéticos, etc. La aplicación de la película adhesiva termofusible en este caso se refleja principalmente en la unión entre la suela y el empeine, especialmente en la unión entre la tira de la sandalia y la suela. Gracias a la rápida fusión y unión de los materiales, el proceso de producción es más sencillo y rápido, a la vez que proporciona una mayor resistencia al agua, ideal para calzado usado en ambientes húmedos.

Las ventajas de la película adhesiva termofusible en sandalias y pantuflas incluyen:

Rendimiento a prueba de agua: la película adhesiva termofusible tiene un buen rendimiento a prueba de agua y es particularmente adecuada para la producción de calzado de verano.

Comodidad y ligereza: Los zapatos pegados con película adhesiva termofusible son más ligeros y no añaden peso innecesario.

Adaptarse al entorno de alta temperatura: la película adhesiva termofusible puede soportar el entorno de alta temperatura en verano y no es fácil que pierda la adhesión a altas temperaturas.

4. Aplicación en calzado infantil

El calzado infantil suele ser ligero, cómodo, duradero y seguro. La película adhesiva termofusible se ha convertido en una opción ideal para la fabricación de calzado infantil gracias a su rápida adhesión y seguridad. Proporciona una adhesión fuerte sin dañar el material del calzado, garantizando así su durabilidad en el uso diario.

Las ventajas de la película adhesiva termofusible en el calzado infantil incluyen:

Seguridad y protección del medio ambiente: la película adhesiva termofusible no es tóxica y no contiene sustancias nocivas, lo que cumple con los estándares de seguridad de los productos para niños.

Evite fugas de sustancias nocivas: en comparación con el pegamento líquido tradicional, la película adhesiva termofusible no libera gases nocivos durante el proceso de curado y es más adecuada para el calzado de los niños.

Durabilidad y comodidad: la unión de películas adhesivas termofusibles puede hacer que los zapatos sean más fuertes sin afectar la comodidad de los mismos.

5. Aplicación en calzado de alta gama

En la producción de calzado de alta gama (como zapatos de marcas de lujo, zapatos personalizados, etc.), los requisitos de los procesos de alta calidad son particularmente estrictos en la selección de materiales. La película adhesiva termofusible se utiliza ampliamente en la producción de calzado de alta gama gracias a su control preciso y su adhesión estable. Esta película adhesiva proporciona una fuerza de adhesión uniforme, evita la penetración o el desbordamiento del pegamento y garantiza la apariencia y la calidad del calzado de alta gama.

Las ventajas de la película adhesiva termofusible en el calzado de alta gama incluyen:

Unión de alta precisión: la película adhesiva termofusible puede proporcionar una unión precisa y duradera sin dañar el material superior.

Conexión sin costuras: puede garantizar que las costuras de los zapatos sean más suaves y no haya marcas de pegamento obvias, manteniendo la apariencia exquisita de los zapatos de alta gama.

Reduce el olor: dado que la película adhesiva termofusible no tiene olor a solvente, puede mantener los zapatos frescos durante su uso.