신발가죽산업

출시일: 2025-03-12

이음매 없는 메쉬 라미네이트, 스테레오타입 천, 홍콩 바오, 이전 뱅 글루, 포스트 뱅 글루, 깔창 합성물, 가죽 전사 하이라이트 필름, 가죽 라벨 등

신발

핫멜트 필름을 스니커즈 메시 프레스 접착제에 적용하여 기존 재봉 공정보다 접착력이 빠르고, 강도가 강하며 외관이 더욱 아름답습니다. 제품의 주요 특징은 다음과 같습니다. A. 사용이 간편하고 노동력이 절감됩니다. B. 높은 박리 강도와 강한 접착력을 지닙니다. C. 우수한 탄성, 인성, 내마모성을 지닙니다. D. 방수, 내수성을 지닙니다. E. PVC, 폴리에스터, 혼방, 면, 나일론, 천, 가죽 및 기타 소재에 적합합니다.

고정관념적인 천

핫멜트 파우더는 열간 압착 직물 생산의 원료 중 하나입니다. 일반 소비자는 일반적으로 40~80도의 눈(eye) 규격을 사용하여 핫멜트 파우더를 직물에 고르게 도포한 후, 오븐에서 가열합니다. 오븐에서 가열된 핫멜트 파우더는 상온에서 즉시 응고되어 직물에 부착됩니다. 가죽 제품(예: 가죽 신발, 핸드백 등) 접착에 사용되는 핫멜트 직물은 표면 처리 없이도 우수한 접착 효과를 얻을 수 있으며, 견고한 압착 안감을 유지하고, 가죽의 팽팽한 겉모습으로 인해 발생하는 부드러움을 보완합니다. 또한, 기존 접착제로는 가죽 주름을 만들 수 없습니다.

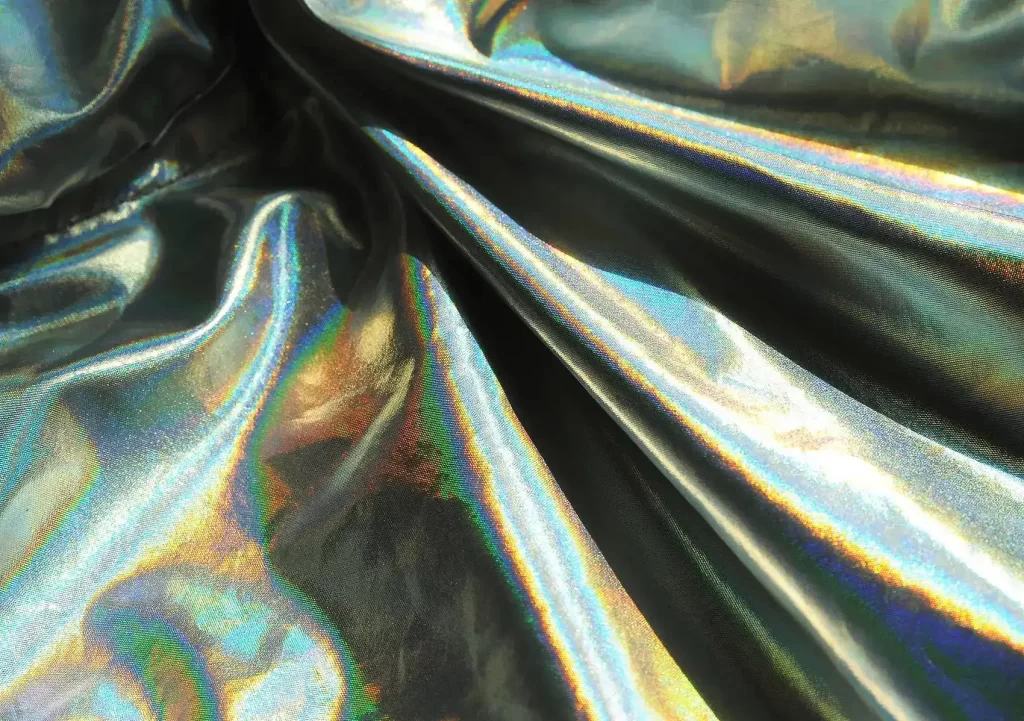

고광택 필름

핫멜트 젤 그레인은 핫멜트 포트 트레져, 고광택 필름 등 필수 원료를 생산합니다. 일반 포트 트레져보다 탄성이 좋고, 변형이나 주름이 잘 지지 않으며, 얇고 경화가 빠른 등의 장점을 가지고 있습니다. 또한 고광택 필름 견뢰도와 밝기가 뛰어나 가죽 신발, 가죽 가방 등 다양한 제품에 널리 사용됩니다. 멜트 메시는 깔창에 적용되어 원단과 바닥 폼의 밀착력을 높여주며, 일반 접착제보다 접착력이 우수하고, 방수, 드라이클리닝, 환경 보호, 균일한 두께로 착용감이 뛰어납니다.

신발용 접착제

프리헬프 접착제는 우수한 환경적 인성, 강한 접착력, 빠른 경화 속도 등의 장점을 가지고 있어 대량 생산에 적합합니다. 주로 신발 헤드에 사용되어 신발 헤드의 강도를 유지하여 신발의 미관과 편안함을 보장합니다. 포스트헬프 접착제는 환경 보호, 우수한 인성, 강한 접착력, 빠른 경화 속도 등의 장점을 가지고 있어 대량 생산에 적합합니다. 주로 발꿈치와 발목 부위의 착용감에 사용됩니다.

1. 스포츠화에의 응용

운동화 제작 과정에서 핫멜트 접착 필름은 갑피 접착, 깔창 고정, 그리고 뒤꿈치 연결에 널리 사용됩니다. 운동화는 일반적으로 합성 피혁, 직물, 고무, 폼 등 여러 겹의 소재로 제작되며, 핫멜트 접착 필름은 이러한 다양한 소재 간의 강력한 접착력을 보장합니다.

스포츠화에 핫멜트 접착 필름을 사용하는 장점은 다음과 같습니다.

향상된 편안함: 핫멜트 접착 필름은 접착 과정에서 재료의 탄성을 손상시키지 않으며 운동화의 편안함을 유지할 수 있습니다.

강력한 내구성: 핫멜트 접착 필름은 운동화의 장기간 마찰과 늘어남을 견뎌내어 신발의 내구성을 향상시킵니다.

신속한 프로토타입 제작: 핫멜트 접착 필름은 경화 시간이 짧아 생산 효율성을 향상시킬 수 있습니다.

2. 가죽신발에 적용

가죽 신발 제조 공정에서 핫멜트 접착 필름은 갑피와 밑창을 접착하거나 가죽과 다른 소재를 겹치는 데 자주 사용됩니다. 가죽의 부드러움과 쉬운 변형 덕분에 핫멜트 접착 필름은 접착 과정에서 가죽의 자연스러운 외관과 질감을 효과적으로 유지할 수 있습니다. 또한, 핫멜트 접착 필름은 기존 접착제의 휘발성 유기 화합물(VOC)로 인한 환경 오염 문제를 방지하여 환경 보호 요건을 충족합니다.

가죽 신발에 핫멜트 접착 필름을 사용하는 장점은 다음과 같습니다.

미학적 측면 개선: 핫멜트 접착 필름은 가죽 표면을 매끄럽게 유지하는 동시에 접착제가 넘쳐 윗부분의 모양에 영향을 미치는 것을 방지합니다.

환경 보호: 핫멜트 접착 필름은 무독성이며 자극적인 냄새가 없어 현대 소비자의 환경 보호 및 건강 요구 사항을 충족합니다.

변형이 쉽지 않음: 기존의 접착 방식과 비교했을 때 핫멜트 접착 필름은 접착제와의 접촉으로 인한 가죽 변형을 피할 수 있습니다.

3. 샌들, 슬리퍼 등에 적용

샌들과 슬리퍼 제작에는 일반적으로 고무, 직물, 합성 소재 등 다양한 소재의 접착이 필요합니다. 이 경우 핫멜트 접착 필름의 적용은 주로 밑창과 갑피, 특히 샌들 끈과 밑창의 접착에 집중됩니다. 핫멜트 접착 필름은 소재를 빠르게 녹여 접착할 수 있어 제작 공정이 간편하고 빠르며, 동시에 뛰어난 방수 기능을 제공하여 습한 환경에서 착용하는 신발에 적합합니다.

샌들과 슬리퍼에 핫멜트 접착 필름을 사용하면 다음과 같은 장점이 있습니다.

방수 성능: 핫멜트 접착 필름은 방수 성능이 뛰어나 특히 여름용 신발 생산에 적합합니다.

편안함과 가벼움: 핫멜트 접착 필름으로 접착된 신발은 더 가볍고 불필요한 무게가 늘어나지 않습니다.

고온 환경에 적응: 핫멜트 접착 필름은 여름철 고온 환경을 견딜 수 있으며 고온에서도 접착력을 잃기 쉽지 않습니다.

4. 어린이 신발에 적용

아동용 신발은 가볍고, 편안하고, 내구성이 뛰어나며, 안전해야 합니다. 핫멜트 접착 필름은 빠른 접착력과 안전성으로 아동용 신발 제조에 이상적인 선택으로 자리 잡았습니다. 핫멜트 접착 필름은 신발 소재를 손상시키지 않고 강력한 접착력을 제공하여 일상생활에서 신발의 내구성을 보장합니다.

어린이 신발에 핫멜트 접착 필름을 사용하는 장점은 다음과 같습니다.

안전 및 환경 보호: 핫멜트 접착 필름은 무독성이며 유해 물질을 포함하지 않아 어린이 제품의 안전 기준을 충족합니다.

유해 물질 누출 방지: 기존의 액상 접착제와 비교했을 때, 핫멜트 접착 필름은 경화 과정에서 유해 가스를 방출하지 않아 어린이 신발에 더 적합합니다.

내구성 및 편안함: 핫멜트 접착제 필름 접합은 신발의 편안함에 영향을 주지 않고 신발을 더 강하게 만들 수 있습니다.

5. 고급 신발에 적용

고급 신발(명품 브랜드 신발, 맞춤 제작 신발 등) 생산 시, 소재 선정에 대한 정밀 공정 요건이 특히 엄격합니다. 핫멜트 접착 필름은 정밀한 제어 능력과 안정적인 접착력으로 고급 신발 생산에 널리 사용됩니다. 핫멜트 접착 필름은 균일한 접착력을 제공하고, 접착제 침투나 넘침을 방지하며, 고급 신발의 외관과 품질을 보장합니다.

고급 신발에 핫멜트 접착 필름을 사용하는 장점은 다음과 같습니다.

고정밀 접합: 핫멜트 접착 필름은 상부 소재를 손상시키지 않고 정밀하고 오래 지속되는 접합을 제공할 수 있습니다.

매끄러운 연결: 신발의 이음새가 매끄럽고 눈에 띄는 접착제 자국이 없어 고급 신발의 세련된 외관을 유지합니다.

냄새 감소: 핫멜트 접착 필름은 용매 냄새가 없으므로 사용 중 신발을 신선하게 유지할 수 있습니다.