The invisible adhesive protector: Unveiling the secrets of water-repellent hot melt adhesive film

Release time: 2025-09-22

Table of Contents

In daily life, we often marvel at the ingenious designs of certain products: a lightweight, breathable outdoor jacket that effectively blocks light rain; a stylish Bluetooth earbud case with a surface that repels water like a duck’s back; sneakers where the tongue and upper seamlessly blend without a trace of stitching.

Behind these marvels lies an unsung hero—water-repellent hot-melt adhesive film. What exactly is it, and what remarkable applications does it have? Today, we’ll take a closer look.

1、Introduction

Simply put, it is a solid adhesive film with water-repellent properties.

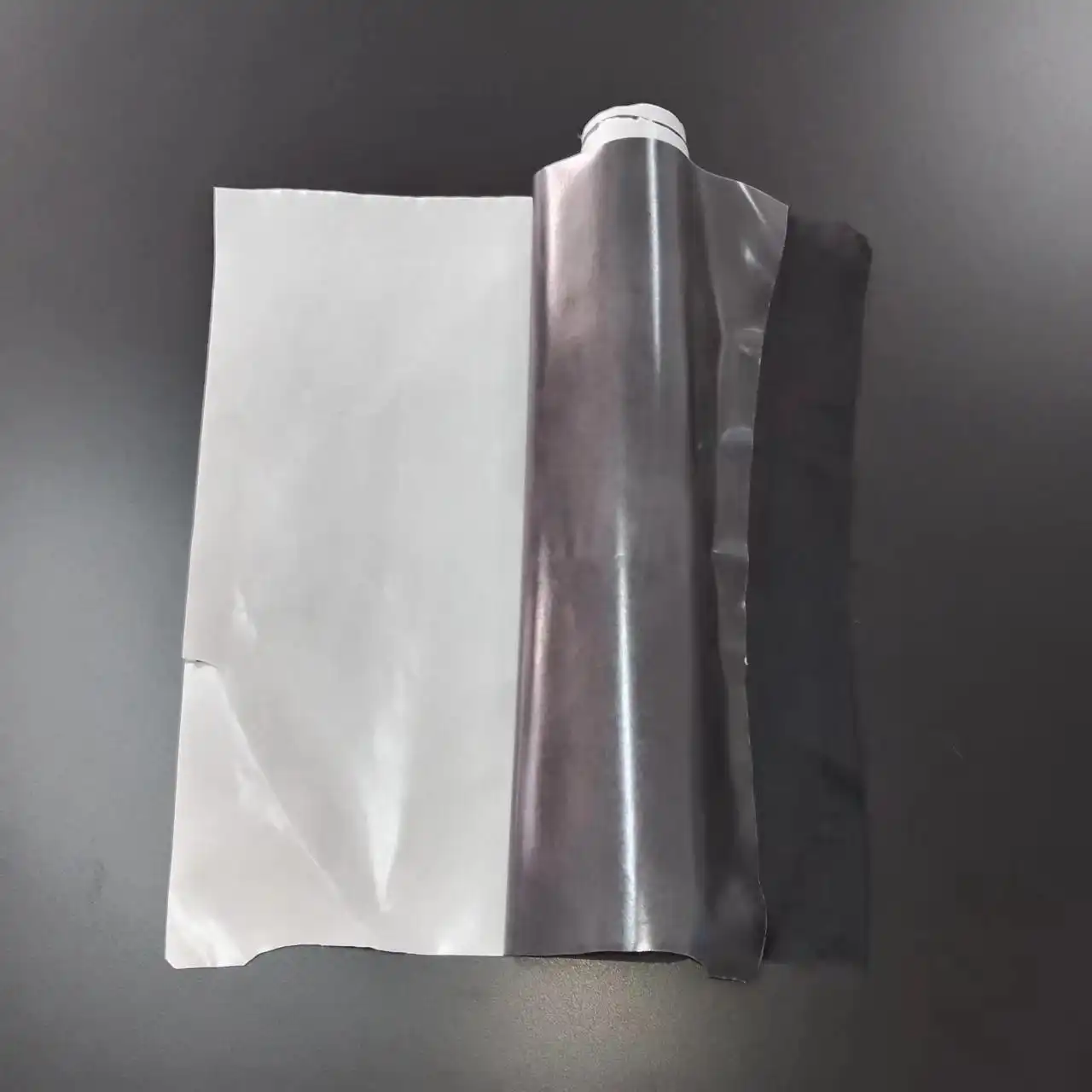

►Form: Typically a roll of white or translucent film with a slightly slippery texture.

►Working Principle: Under high temperature and pressure, the adhesive film melts into a viscous flow state, permeating into the pores of the substrate material. Upon cooling and curing, it forms a robust adhesive layer. Simultaneously, its inherent chemical properties or specialized composite coating impart exceptional water-repellent performance to the bonded area.

2、Advantages

►Seamless bonding

Replacing traditional stitching, it achieves seamless bonding between fabric layers, offering an aesthetically pleasing finish while eliminating the risk of leakage through needle holes.

►Windproof and waterproof

Effectively blocks the penetration of liquids (rainwater, beverages, etc.) while providing wind resistance.

►Breathable and moisture-wicking

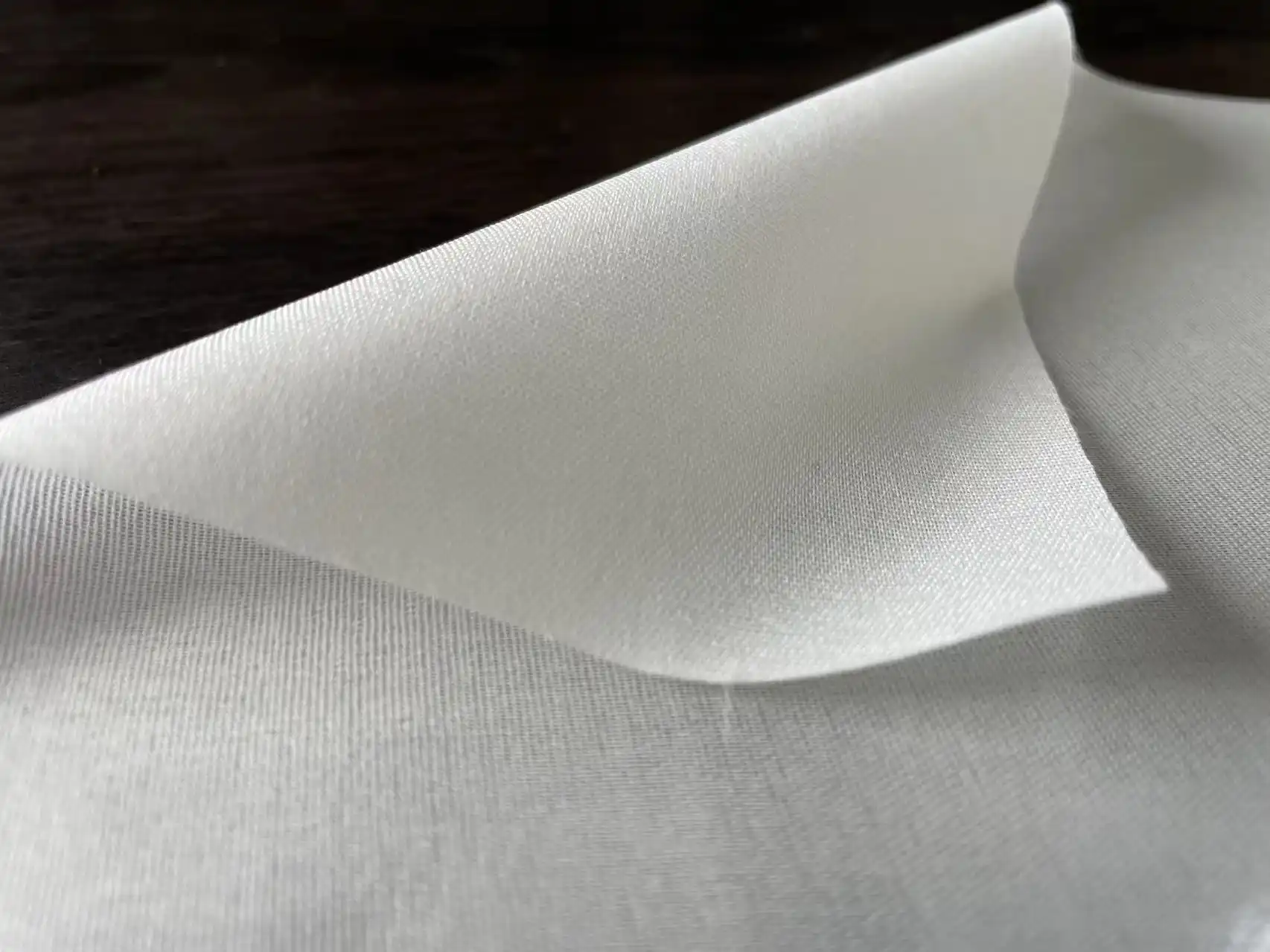

The adhesive film bonds without blocking the material’s micro-pores, ensuring breathable comfort for the garment.

►Soft and form-fitting

After bonding, the fabric retains its original feel and softness without any stiffness.

3、Application

►Outdoor Sports and Functional Clothing

Waterproof Sealed Seams: Narrow water-repellent adhesive films are applied to the seams of jackets, raincoats, and skiwear. Using a heat press machine, these films are fused to form sealed seams, completely preventing rainwater from seeping through stitching. This is a key process in manufacturing high-end waterproof apparel.

Fabric Laminating: An outer waterproof fabric layer, a breathable membrane interlayer (such as GORE-TEX), and an inner lining fabric are bonded together using a heat-activated adhesive film. This creates a “sandwich” composite material with waterproof and moisture-permeable functionality.

►Footwear & Accessories Industry

Footwear: Used for bonding shoe tongues, uppers, waterproof boot covers, and similar components to eliminate friction from stitching and prevent leakage points, enhancing overall integrity and waterproofing.

Luggage & Bags: Applied to waterproof roll-top closures, waterproof compartments, and logo bonding on backpacks and handbags to boost functionality and elevate premium quality.

►Home Furnishings & Automotive Interiors

Home Furnishings: Laminating and edge sealing for waterproof bedspreads, sofa covers, tablecloths, and similar products.

Automotive: Laminating interior materials such as headliners, door panels, and floor mats. The adhesive film must not only be splash-resistant but also withstand extreme temperatures and resist aging.

Choose Anhui Tomis, you will get:

Professional technical support: to provide you with the most suitable choice of adhesive film and embossing program.

High-quality products: strictly control the production process to ensure that each meter of film is of excellent quality.

Perfect after-sales service: to solve your worries, so that you can use at ease.

Contact us now for more information about adhesive film!